Reverse Engineering

Precise Reverse Engineering of existing objects by high-resolution detection of surfaces.

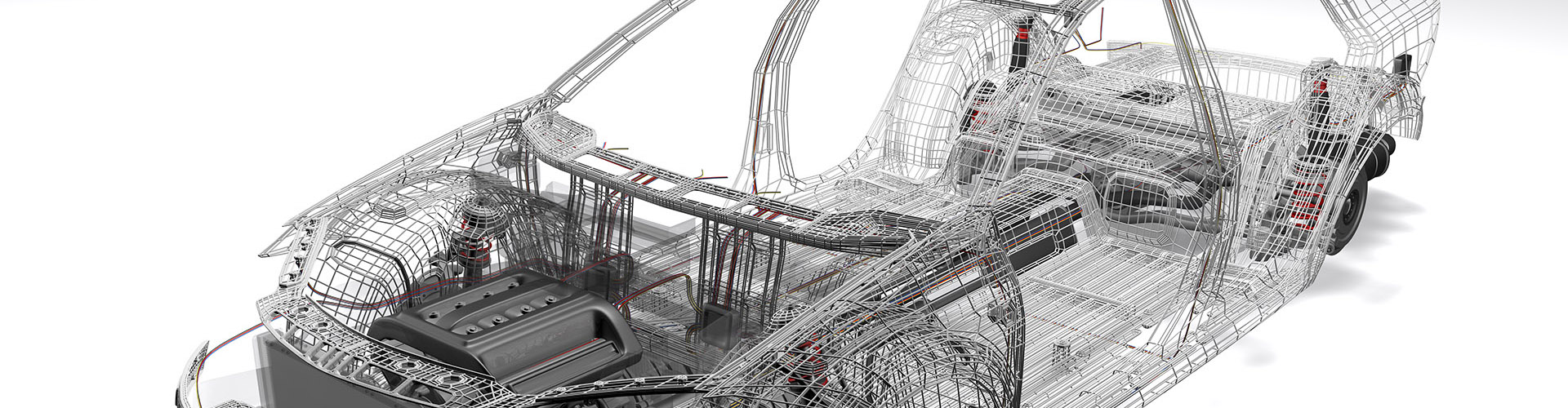

The term "reverse engineering" combines services for detecting already existing objects - usually a workpiece or prototype - with high precision and converting them into a digital model. The technique of Reverse Engineering is particularly used in production control or redesigning.

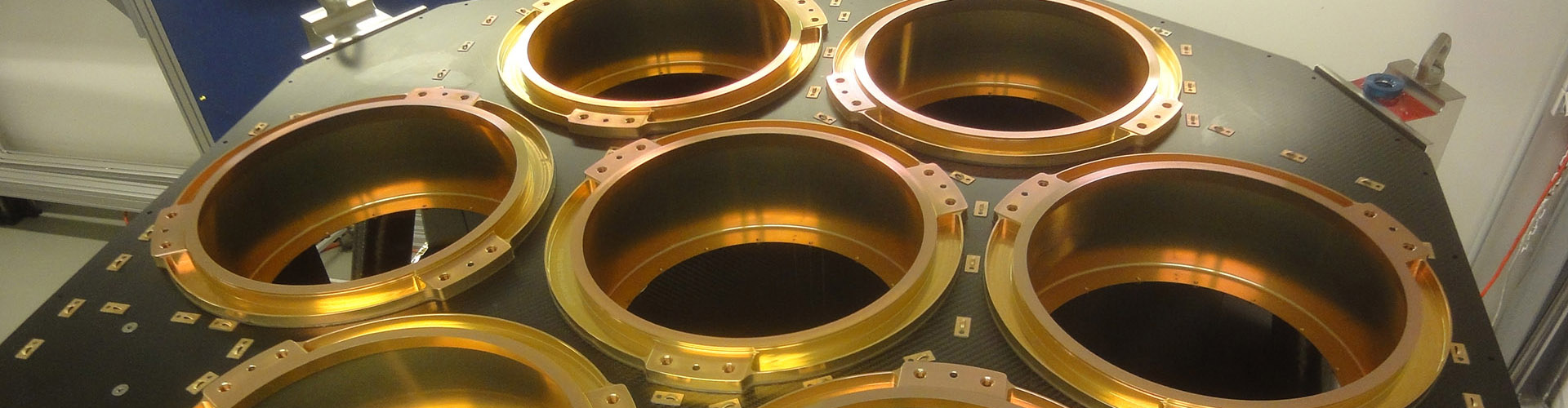

An essential prerequisite is to digitise the object including edges and curvatures as precisely as possible. Our systems provide an accuracy

of up to 50 micrometers and can cover measurement volumes of up to 18 meters.

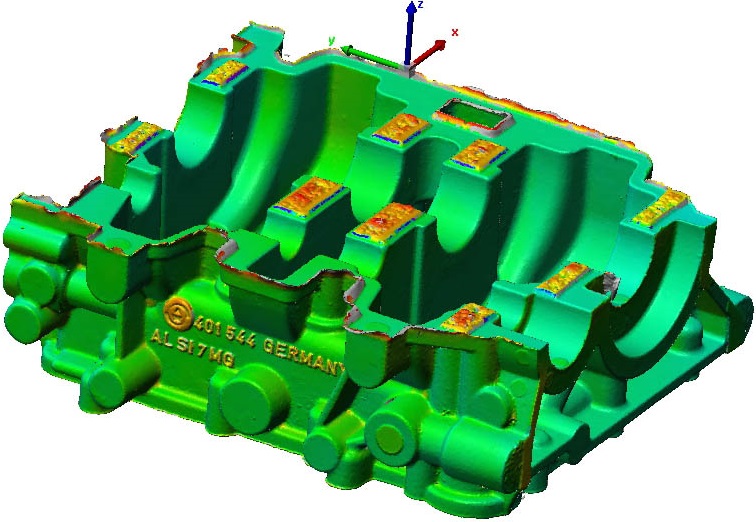

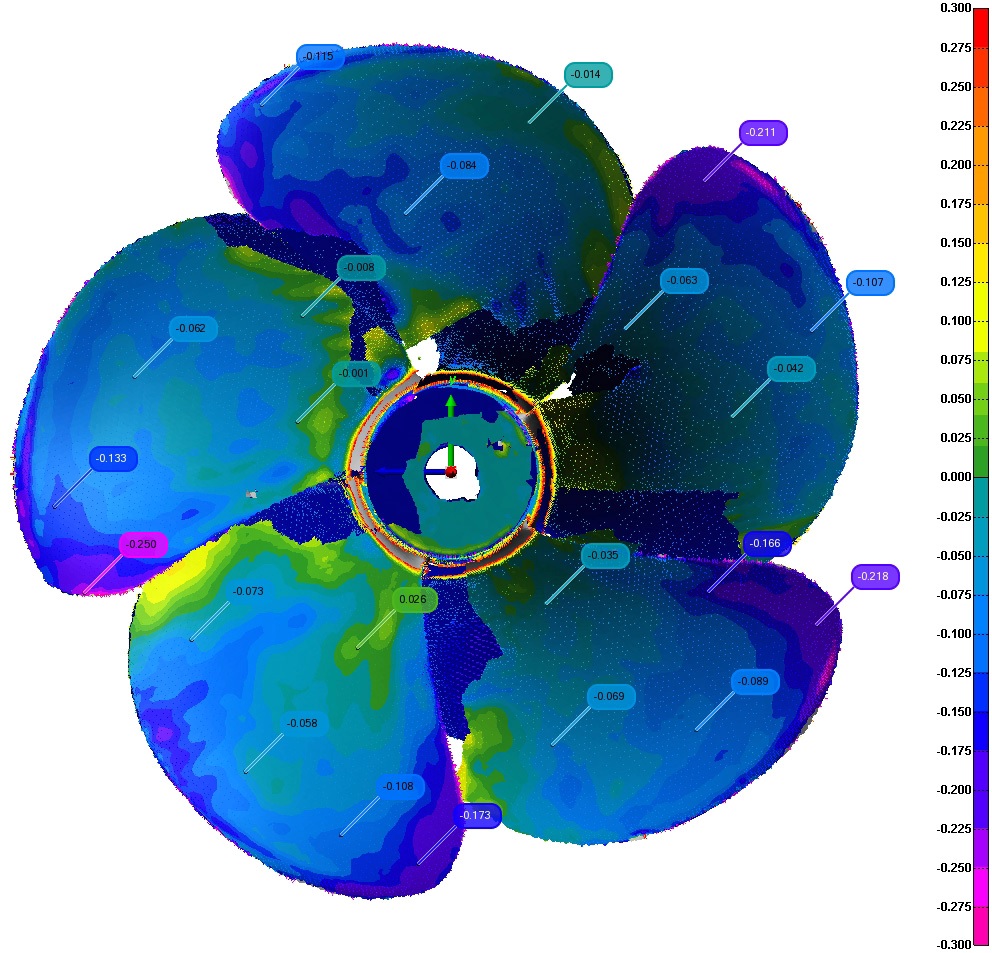

The modeling of the data is done either by using elementary geometric forms such as circles, planes, cylinders, etc. or any freeform surfaces, often using NURBS (Non Uniform Rational B-Splines).

Optionally, the acquired data can be subjected to a normative-actual value comparison by using an existing CAD model of the workpiece.

Besides 3D Laser Scanning and Laser Tracking, hand-held measuring systems are used increasingly for Reverse Engineering tasks. The advantages of these systems are an enhanced flexibility and the possibility of non-contact measurements of stationary and moving objects.

For these purposes, dhp:i uses the following hand-held scanners: For Reverse Engineering come, dhp:i uses the following hand-held scanners, which differ substantially by their accuracies and measurement volumes:

Leica T-Scan

Artec Eva and Spider

Trimble DPI-8